Putting the “Science” in “Science Fiction” – Regenerative Plastics

A common factor of technology in science fiction is that it seems to last far longer than ours, and is able to stand up to much heavier punishment. While a modern cell phone can be rendered totally useless if it is dropped on too hard a surface, the gadgets, vehicles, and machines in science fiction are capable of surviving all kinds of harsh conditions. The search for a way to improve the durability of the items we use every day is the focus of a lot of research, and falls into two main camps. The first and simplest is making materials tougher and able to withstand more abuse, a field of research that has been making great strides through the use of nanotechnology, carbon nanotubes, and other amazing advances in material technology. Although these advances have done a lot to make materials more resistant to damage it does little once the damage is done. This is where the second area of this research, regeneration technology, comes in.

So far the ability to regenerate damage has mostly been confined to living organisms, but scientists are hoping to create machines that are capable of self-repair. From the simple and mostly off-camera regenerative abilities of the Transformers, to the dramatic and impressive repair capabilities of the T-1000, the machines of science fiction are able to continue despite the damage they suffer because they are able to heal it like a living creature could. For a long time this ability has been beyond the reach of scientists, but now these secrets are beginning to be unlocked. A particular focus of this research is on the creation of regenerative plastics, and several scientists have made breakthroughs in recent years.

One of these breakthroughs involves the creation of plastics that alert their users to damage. These involve changes to the chains that make up plastics, so that when they are broken by a scratch or impact they create a red stain on the plastic’s surface. In this way even damage that would normally be invisible can be seen by a casual inspector. This will be especially useful in fields where even small damage can be disastrous, like in the aerospace industry or the military. This plastic goes one step further though, as the chains are able to repair the breaks between them when exposed to bright or UV light, allowing repairing a small scratch to be as simple as leaving the plastic outside on a bright day. These smart plastics are an amazing achievement, but they are still not able to repair the type of major damage that leaves huge gaps or holes in a piece of plastic. Even with that type of damage, there is still hope though.

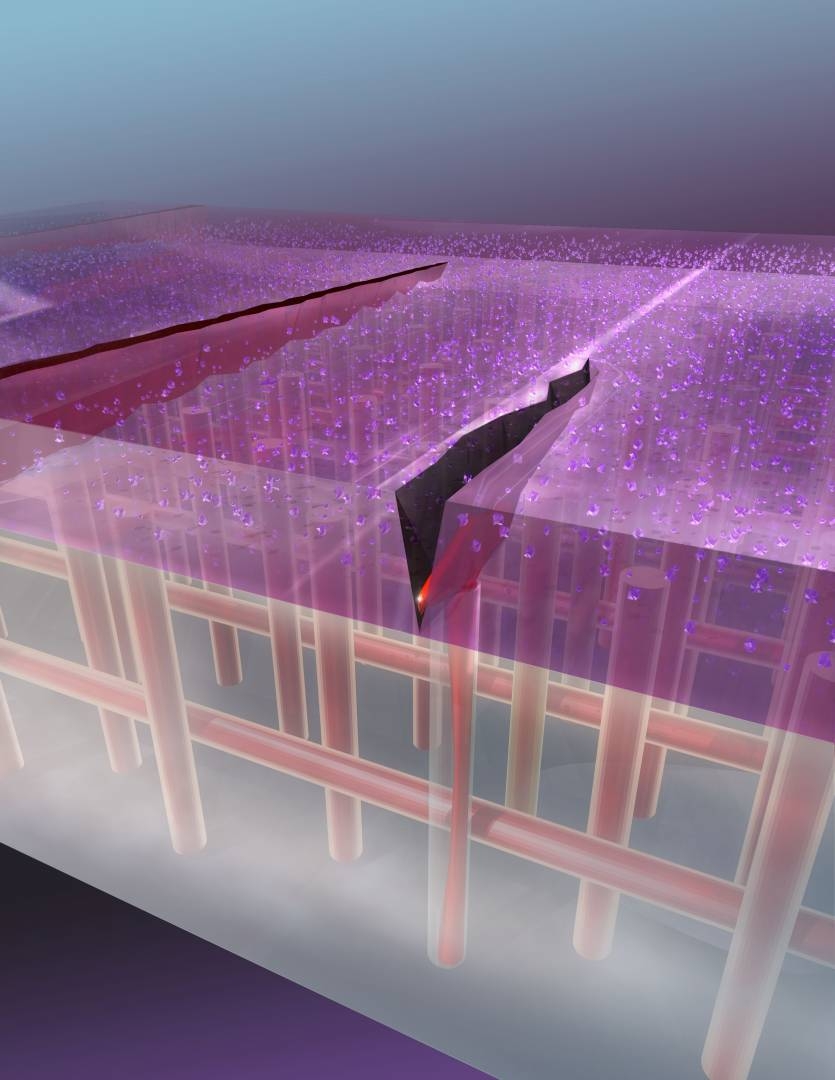

Another form of regenerative plastic that is currently under development will be able to heal even large gaps, and will not require any outside stimulus to do so. This technique, spearheaded by researchers in Illinois, imitates natural healing techniques and applies them to plastic. In this technique the plastic is formed with two sets of hollow capillaries within its structure, each of which is then filled with a regenerative chemical. When damage occurs the chemicals within the capillaries mix, creating a gel that flows into the hole and then hardens to the consistency of the surrounding plastic, sealing the gap entirely. A similar technique uses small capsules imbedded in the material. This technology will allow plastics to repair much larger gaps, and when the two techniques are combined together the result will be a new type of plastic that will be able to withstand a huge amount of abuse and still retain its shape and strength.

These regenerative plastics are amazing, and when combined with new research aimed at creating plastics that seek to imitate or even improve on the strength of steel we are sure to see plastic materials in a whole new way, and they may even become one of our main building materials. Other research towards creating plastic out of environmentally friendly, and even bio-degradable, materials and techniques will only further cement plastic’s role as one of the materials of the future.